|

Holding Frame: I built this frame out of strips of oak wood to withstand the heat of the oven. It is hinged by brass cabinet hinges and secured closed using brass cabinet latches. |

|

| |

|

|

Holding Frame: Here is a picture of the open frame. My newest update to this design includes rubber weather stripping along the inside of the frame to more securely hold the styrene. |

| |

|

|

Forming Table: I built this out of two large pieces of plywood sandwiched around a frame of pine 1.5" x 0.5" strips of wood. This creates a large air pocket between the two sheets of wood. The top piece of wood contains over 150 holes that lead to the air pocket in the middle of the two boards. I have added a square of foam weather stripping to the board that matched the dimensions of my forming frame. |

| |

|

|

Forming Table: The bottom piece of wood contains one large hole that leads to the air pocket in the middle of the two boards. This hole has been fitted with a floor flange to easily attach the table to the shop vac. |

| |

|

|

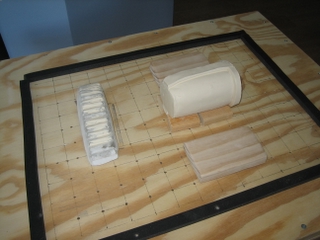

Forming Table: This is a picture of the forming table with a few molds ready to be formed. |

| |

|

|

Forming Table: This is another picture of the forming table with a few molds ready to be formed. |